-

WE STRIVE TO EXCEED OUR CUSTOMER'S EXPECTATIONS.Innovation has been a guiding force at Sanks Machining for over 20 years.

WE STRIVE TO EXCEED OUR CUSTOMER'S EXPECTATIONS.Innovation has been a guiding force at Sanks Machining for over 20 years. -

WE ARE PROUD TO BE A FULL SERVICE MACHINE SHOP.Let us use our expertise to help you with all of your manufacturing challenges.

WE ARE PROUD TO BE A FULL SERVICE MACHINE SHOP.Let us use our expertise to help you with all of your manufacturing challenges.

About Sanks Machining

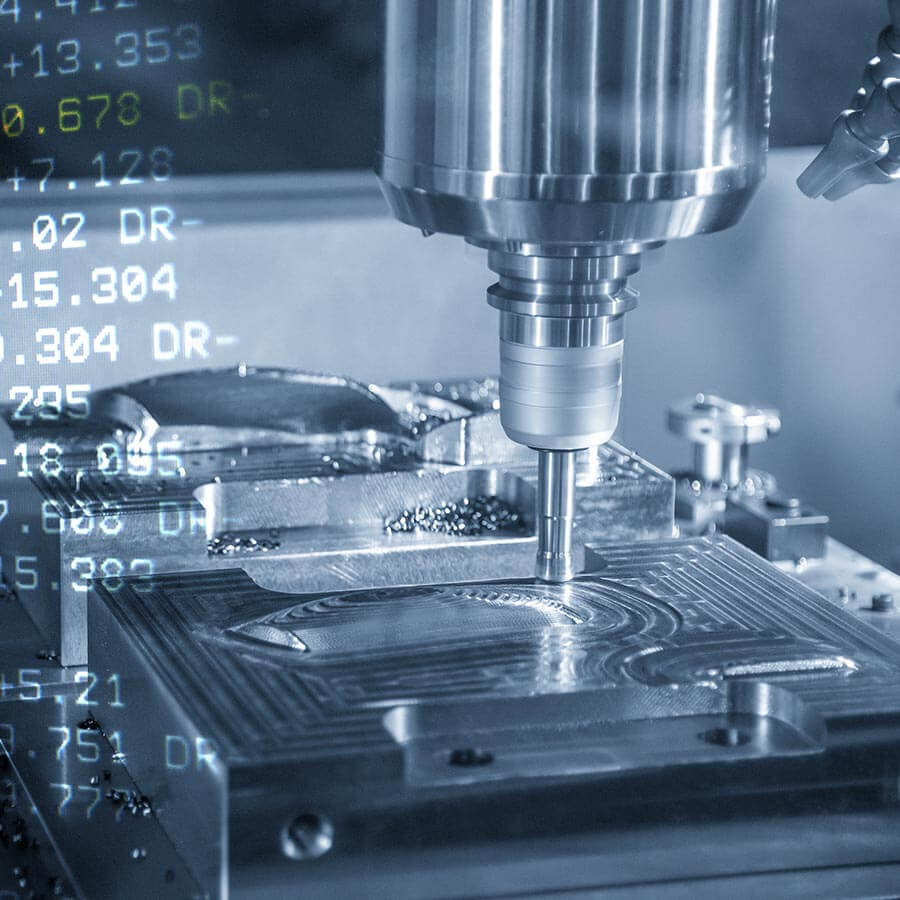

Sanks Machining, Inc. has the capabilities to manufacture intricate small parts and tooling all the way to complete design/build, fully functioning, large machines and assemblies. The manufacturing production is achieved by the use of both vintage and modern tooling from a mid-20th century boring mill to state-of-the-art CNC machines capable of performing multiple operations on numerous parts along varying axis’. They also have in house design capabilities through the use of the industry’s most up to date computer aided design modeling software.

Capabilities

Multi-Axis Turning & Milling

Utilizing the most modern CNC machining technology to manufacture components from a wide array of materials.

Swiss Turning

Producing high volumes of precisions parts with tight tolerances.

Traditional Machining

Repairing and manufacturing products with modern, as well as vintage, manual mills and lathes.

Surface Grinding

Creating high surface finishes while holding tight tolerance flatness and parallelism.

Wire EDM

Cutting intricate and complex shapes though the use of electrical discharge machining.

Welding & Fabrication

Arc, mig, tig, and pulse welding, along with custom frame and weldment fabrication.

Hand Scraping

Hand scraping surfaces to ensure a precision machine fit, proper wear and adequate oil distribution.

On-site Portable Machining

Ability to reduce downtime by performing remote machining operations in the field.

Machine & Fixture Assembly

Delivering fully functional automatic machines and both dynamic, and static, fixturing.

Prototyping

Working with customers to develop and implement new products and help improve and modernize outdated designs.

Design & Engineering

Using the industry’s finest computer aided modeling software and coordinate measuring machines to design new products and reverse engineer parts that are no longer in production.

Quality Control & Inspection

Inspecting and reporting on parts to maintain quality and consistency before delivery.

Industries We Serve

Why Choose Sanks Machining

With robust growth over the years and a change in ownership, the core principles of running a successful business have never changed: going above and beyond customer expectations in every aspect, hard work and dedication, and employing highly skilled craftsmen with an intense attention to detail and quality.

Craftmanship

We take pride in our parts. We strive to make components that exceed our customer’s expectations.

Services

We are a full service machine shop offering a wide array of services for our customers.

Innovation

Innovation has been a guiding force at Sanks Machining for over 20 years.

Get In Touch With Us

Please feel free to contact us for any inquiries. Your comments and suggestions are very important to us. Please do not hesitate to email us.